Specialized coating and lamination for flat and tubular PP/HDPE woven fabrics

Reinvent your packaging - from basic to brilliant

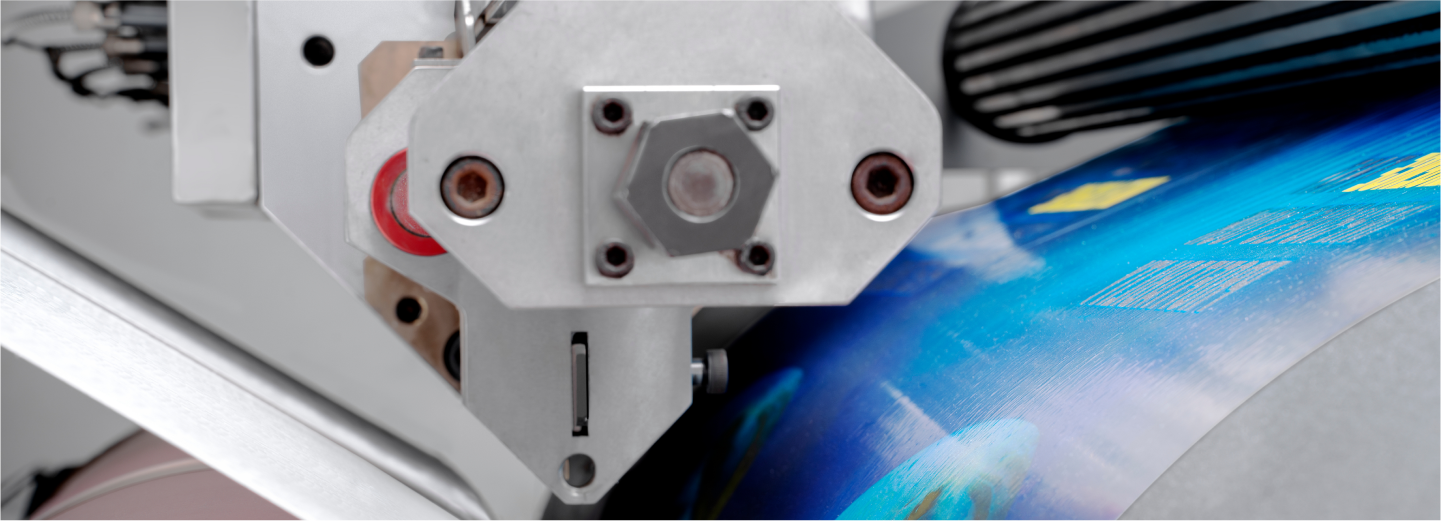

Extrusion coating machines on PP/HDPE woven fabric. The extrusion machines are designed to coat PP or LDPE polymer or a combination on both sides in a single operation.

Excellent coating adhesion

Ensuring long-lasting performance and durability of the fabric

Modular design for ultimate flexibility

Enabling easy adaptation and scaling to meet your unique needs and a variety of applications

Precision registration control

Ensuring accurate image alignment during lamination, maintaining the integrity of printed designs

Uniform coating thickness

Optimizes barrier properties, adhesion, and other critical performance characteristics

Enhance your products with our Coating & Lamination series

-

200 m/min

Line speed

-

330 kg/hr

Melt capacity

Lamicoat Classic

Comprehensive range of extrusion coating and lamination solutions, engineered to meet the diverse needs of the woven fabric industry

-

High speed

-

Auto roll changeover

-

For specialized applications

-

200 m/min

Line speed

-

330 kg/hr

Melt capacity

-

150 m/min

Line speed

-

400 kg/hr

Melt capacity

Lamicoat Prime

Versatile and cost-effective extrusion coating solutions to handle a wide array of substrates, including HDPE and PP flat or circular woven fabrics, non-woven materials, BOPP films and papers, making it exceptionally adaptable for various applications

-

Economical solution

-

Modular design

-

For versatile applications

-

150 m/min

Line speed

-

400 kg/hr

Melt capacity

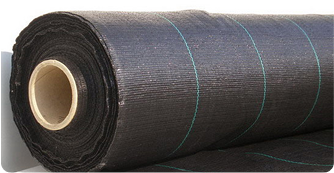

Create a range of products with our Coating machines

Agrotex

Buildtex

Packtex

Geotex